| |

|

|

| |

|

| |

|

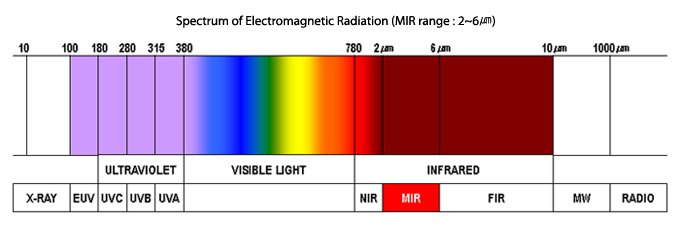

We are leading the technology in the fields of MIR (Mediumwave Infra-Red) Drying System in Korean market. We use a practical approach in applying our MIR drying Technology, thoroughly satisfying your process requirements. We provide infinitely adjustable mediumwave infra-red for accurate and uniform product drying. Whether your process calls for liquid or powder, wax or adhesive

coatings in all industries, Our High Efficiency MIR Drying Technology can provides you with the precise drying required,

producing the perfect and fast and economic drying. Every time ! |

| |

|

MIR provides more effective energy to water base ink or paints, plastics, glass, film drying applications than conventional drying methods. This means shortened cycle times, reduced plant space requirements, increased productivity, improved product quality and lower operating costs. The savings from reduced energy consumption alone can often justify a new installation. |

| |

|

|

|

| |

① Excellent energy efficiency

① - Mir energy change electirc power to electromagnetic power and it transfer energy to substrate at the velocity of light

① - with excellent efficiency.

① - Maintaining the drying condition of existed ir/heat blow system (Temp drying characteristic of paints), high effiency

① - drying is available different from nir drying system. |

② High energy absorption -> High efficiency / high speed drying

① - Coated metals, polymer resins (Plastic, various films, etc), glasses (LCD, PDP, CRT, etc), water-soluble paints

① - (inks, paints, etc), etc, have superior energy absorption ability within the mir area like 2~6㎛ frequency area, so, they

① - have excellent energy transfer characteristic and high speed drying is also available.

|

| ③ High speed drying compared to existed heat blow drying of traditional method. |

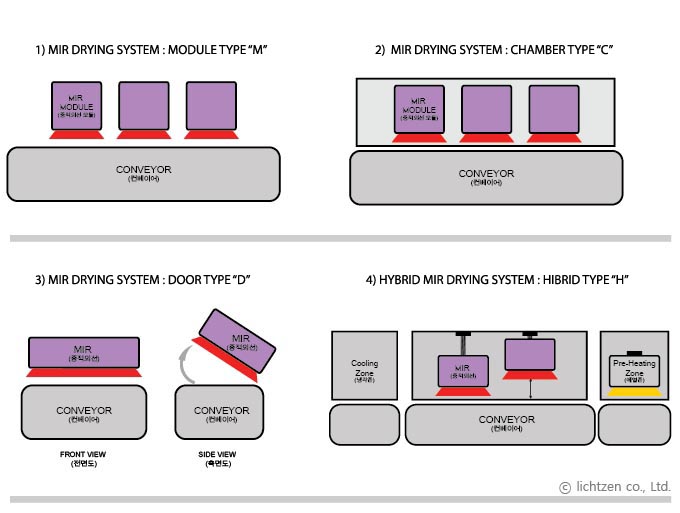

| ④ Easily applicable and installable by compact designed MIR Module structure and power supplier. |

| ⑤ Line up various capacity of modules can apply various application system. |

⑥ Can construct MIR drying system easily with modularization system in the field of no knowledge of MIR system

(Print, coating, FPD, etc) |

| ⑦ Cost down the production facility cost only with MIR Module and power supplier. |

| ⑧ Supporting various input/output signals and easily communicates with other systems. |

|

|

| |

|

|

| |

|

| |

| Description |

Model (Size) |

| MS 3054 H |

MS 6053 H |

MS 9108 H |

MS 12063 C |

MS 21063 C |

비 고 |

System

Dimension |

Length (L) mm |

5000 |

5000 |

10000 |

6000 |

6000 |

|

Width (W) mm |

1070 |

1070 |

1070 |

1000 |

1000 |

Module Type |

| Height (H) mm |

1350 |

1350 |

1350 |

1350 |

1350 |

|

Conveyor

(Hc) mm |

800 |

800 |

800 |

800 |

800 |

|

Module Height Adjustment |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Conveyor Speed (m/min) |

0 ~ 5 |

0 ~ 5 |

0 ~ 5 |

0 ~ 5 |

0 ~ 5 |

|

Conveyor Material |

Teflon / SUS |

Teflon / SUS |

Teflon / SUS |

Teflon / SUS |

Teflon / SUS |

Mesh Belt |

Conveyor Centering

Adjustment Unit |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Absorption System |

Optional |

Optional |

Optional |

Optional |

Optional |

|

Anti-Static Electricity Unit |

Optional |

Optional |

Optional |

Optional |

Optional |

|

| |

|

|

|

|

|

|

Module Quantity |

4 |

3 |

8 |

3 |

3 |

|

Module

Type |

Model |

MS3-6 |

MS6-13 |

MS9-19 |

MS12-13 |

MS21-25 |

|

Length (L) mm |

1070 |

1070 |

1070 |

1000 |

1000 |

|

Width (W) mm |

200 |

400 |

900 |

500 |

500 |

|

Height (H) mm |

350 |

350 |

350 |

350 |

350 |

|

Lamp Array |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

|

Housing Material

(SUS / Steel) |

○ |

○ |

○ |

○ |

○ |

|

Actual Drying Width (mm) |

600 |

600 |

600 |

800 |

800 |

|

MIR

Lamp |

Heating Length

(mm) |

700 |

700 |

700 |

350 |

350 |

|

Overall Length

(mm) |

850 |

850 |

850 |

500 |

500 |

|

Lamp Wattage

(W) |

2100 |

2100 |

2100 |

1050 |

1050 |

|

Wattage / Cm

(W/Cm) |

30 W/Cm |

Lamp Voltage (V) |

110 |

110 |

110 |

55 |

55 |

|

Module

Capacity |

Lamp Quantity

(EA) |

3 |

6 |

9 |

12 |

24 |

|

Module Capacity

(kW) |

6.3 |

12.6 |

18.9 |

12.6 |

25.2 |

|

Power Input |

220V, 3P |

220V, 3P |

220V, 3P |

220V, 3P |

220V, 3P |

|

Exhaustion |

N/A |

N/A |

N/A |

N/A |

N/A |

|

Air Cooling |

○ |

○ |

○ |

○ |

○ |

|

Reflector (SUS / Aluminum) |

○ |

○ |

○ |

○ |

○ |

|

Non-Explosion structure

(Optional) |

N/A |

N/A |

N/A |

N/A |

N/A |

|

| |

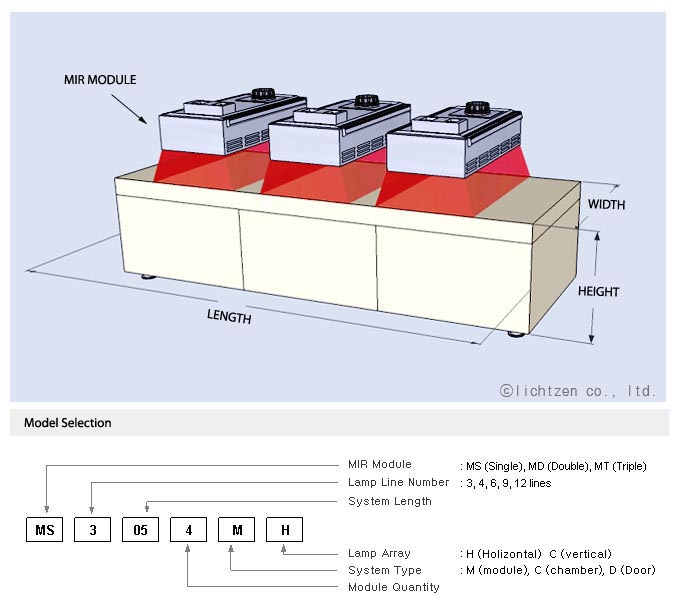

※ Remark

1. The array method for MIR Lamps could be apply according to customer’s requested configuration or suggestion.

2. System Length = Variable, System Width : (Chamber type = Module length + 300 mm), (Module type = Module length),

2. System Height = 800 mm + variable. |

|

| |

|

| |

Power Supply |

Input Power |

AC220V, 1P/3P , 60 Hz |

|

SCR |

Model |

LT-2030A |

LT-2050A |

LT-2075A |

LT-2030A |

LT-2050A |

|

Capacity (A) |

30A |

50A |

75A |

30A / 30A |

50A / 50A |

|

Quantity (Ea) |

4 |

3 |

8 |

3/3 |

3/3 |

|

Module Zone control |

○ |

○ |

○ |

○ |

○ |

|

Heating Zone control |

1 Zone |

1 Zone |

1 Zone |

3 Zone |

3 Zone |

|

Control

Interface |

Control Signal

(External -> Unit) |

Remote (External) control and monitoring by PLC or Automation system (5 ~ 24V contact) |

Lamp On command |

|

Lamp Off command |

|

Power Output Control (0 ~ 100) |

|

Status Signal

(Unit -> External) |

Lamp lit on signal |

|

Lamp lit on fail signal |

|

Cooling fan error signal |

|

Over temperature error signal |

|

Over current signal |

|

Operation |

Auto / Manual |

|

HMI

(Human Machine Interface) |

Touch Screen |

Optional |

Dimension |

TBA |

TBA |

TBA |

TBA |

TBA |

|

Box Material |

Stainless Steel or Steel |

Optional |

Weight |

TBA |

TBA |

TBA |

TBA |

TBA |

|

Non-Explosion structure

(Optional) |

TBD |

TBD |

TBD |

TBD |

TBD |

Optional |

| |

※ Notice

1. Above specification can be changed without notification for our quality improvement.

2. Except for above specification, it could be manufacture according to customer’s requirements. |

|

| |

|

| |

| Description |

Model (Size) |

| MS 9158 H |

MD 6158 H |

MS 12103 H |

MS 24156 H |

Remark |

| System |

System

Dimension |

Length (L) mm |

15000 |

15000 |

10000 |

13000 |

|

Width (W) mm |

1370 |

2120 |

1300 |

1300 |

Chamber Type |

| Height (H) mm |

1350 |

1350 |

1350 |

1350 |

|

Conveyor

(Hc) mm |

800 |

800 |

800 |

800 |

|

Module Height Adjustment |

Optional |

Optional |

Optional |

Optional |

|

Conveyor Speed (m/min) |

0 ~ 5 |

0 ~ 5 |

0 ~ 5 |

0 ~ 5 |

|

Conveyor Material |

Teflon / SUS |

Teflon / SUS |

Teflon / SUS |

Teflon / SUS |

Mesh Type |

Conveyor Centering

Adjustment Unit |

Optional |

Optional |

Optional |

Optional |

|

Absorption System |

Optional |

Optional |

Optional |

Optional |

|

Anti-Static Electricity Unit |

Optional |

Optional |

Optional |

Optional |

|

MIR Drying Zone |

Drying Zone Length (LM) mm |

8000 |

8000 |

5000 |

5000 |

|

Module Quantity |

8 |

8 |

3 |

6 |

|

Module

Type |

Model |

MS9-19 |

MD6-25 |

MS12-13 |

MS24-25 |

|

Length (L) mm |

1070 |

1820 |

1000 |

1000 |

|

Width (W) mm |

900 |

900 |

500 |

500 |

|

Height (H) mm |

350 |

350 |

350 |

350 |

|

Lamp Array |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

|

Housing Material (SUS / Steel) |

○ |

○ |

○ |

○ |

|

Actual Drying Width (mm) |

600 |

1300 |

800 |

800 |

|

MIR

Lamp |

Heating Length

(mm) |

700 |

700 |

350 |

350 |

|

Overall Length

(mm) |

850 |

850 |

500 |

500 |

|

Lamp Wattage (W) |

2100 |

2100 |

1050 |

1050 |

|

Wattage / Cm

(W/Cm) |

30 W/Cm |

Lamp Voltage (V) |

110 |

110 |

55 |

55 |

|

Module

Capacity |

Lamp Quantity

(EA) |

9 |

12 |

12 |

24 |

|

Module Capacity

(kW) |

18.9 |

25.2 |

12.6 |

25.2 |

|

Power Input |

220V, 3P |

220V, 3P |

220V, 3P |

220V, 3P |

|

Exhaustion |

○ |

○ |

○ |

○ |

|

Air Cooling |

○ |

○ |

○ |

○ |

|

Reflector (SUS / Aluminum) |

○ |

○ |

○ |

○ |

|

Non-Explosion structure

(Optional) |

TBD |

TBD |

TBD |

TBD |

|

| |

※ Remark

1. The array method for MIR Lamps could be apply according to customer’s requested configuration or suggestion

2. System Length = Variable, System Width : (Chamber type = Module length + 300 mm), (Module type = Module length),

2. System Height = 800 mm + variable. |

|

| |

Pre-Heating Zone |

Pre-Heating Zone Length

(LP) mm |

2000 |

2000 |

2000 |

2000 |

|

Heater Type (MIR / Hot Air) |

○ |

○ |

○ |

○ |

Optional |

Target Temperature |

80 ℃ |

80 ℃ |

80 ℃ |

80 ℃ |

Adjustable |

| |

|

|

|

|

|

Cooling Zone |

Cooling Zone Length

(LC) mm |

5000 |

5000 |

3000 |

5000 |

|

Cooler Type |

Air / Cooled Air |

Air / Cooled Air |

Air / Cooled Air |

Air / Cooled Air |

|

Target Temperature |

40 ℃ |

40 ℃ |

40 ℃ |

40 ℃ |

|

| |

|

|

|

|

|

Power Supply |

Input Power |

AC220V, 1P/3P, 60 Hz |

|

SCR |

Model |

LT-2075A |

LT-2050A |

LT-2030A |

LT-2050A |

|

Capacity (A) |

75A |

50A |

30A / 30A |

50A / 50A |

|

Quantity (Ea) |

8 |

16 |

6 |

6 |

|

Module Zone control |

○ |

○ |

○ |

○ |

|

Heating Zone control |

8 Zone |

8 Zone |

3 Zone |

6 Zone |

|

Control

Interface |

Control Signal

(External -> Unit) |

Remote (External) control and monitoring by PLC or Automation system (5 ~ 24V contact) |

Lamp On command |

|

Lamp Off command |

|

Power Output Control (0 ~ 100) |

|

Status Signal

(Unit -> External) |

Lamp lit on signal |

|

Lamp lit on fail signal |

|

Cooling fan error signal |

|

Over temperature error signal |

|

Over current signal |

|

Operation |

Auto / Manual |

|

HMI

(Human Machine Interface) |

Touch Screen |

Optional |

Dimension |

TBA |

|

TBA |

TBA |

|

Box Material |

Stainless Steel or Steel |

Optional |

Weight |

TBA |

|

TBA |

TBA |

|

Non-Explosion structure

(Optional) |

TBD |

|

TBD |

TBD |

Optional |

| |

※ Notice

1. Above specification can be changed without notification for our quality improvement.

2. Except for above specification, it could be manufacture according to customer’s requirements. |

|

|

|

|

|