|

|

Features |

|

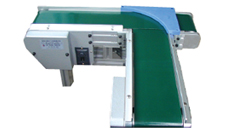

Uni-con frame is Al compressed profile structured. Being anodized & coated, it has strong intensity & corrosion resistance. T shape grooves on the frame makes it available for users to add brackets, sensors or cylinders easily at the position they need, just by inserting rectangle shaped nut, T-nut & T-bolts into the grooves. Protrusion parts, chain cover or S/W control unit can be mounted regardless conveying directions. (Standard type in the above picture: mounts on the left side of conveying direction.)

Motor & control unit is covered entirely preventing damages. Belt surface is clean-conveyor type preventing pollution. Standard belts width would come 50~ 120mm & lead time is 2 or 3 days. (including installation and test running) |

|

|

|

MAINTENANCE |

|

Every parts are assembled by bolts, easy to be assembled or disassembled.

All units & parts are standardized & quality equalization & compatibility is achieved by this. |

|

|

|

UNI-CON BELT CONVEYOR |

|

Considering the convenience of users, it is designed to be a compact structure, which is more clean & lighter. There are various sizes and types; belts size varies from 50 to 120mm & length from 0.2m~ 20m.

It can carry from ultra small objects to 50kg weighed heavy parts(/M). Therefore wider choice for users is available.

|

|

|

|

|

Applications |

|

Precision manufacturing

of substrate, electronic & electrical components, Clean room,

Assembly line, Inspection line, Packaging line, Conveying line

& others. Any automatized factory site can be applied with.

|

|

|

Other

Conveyors

Other

Conveyors

Other

Conveyors

Other

Conveyors